ACERA™ daGama

daGama

12-strand HMPE rope with cover

daGama

12-strand HMPE rope with cover

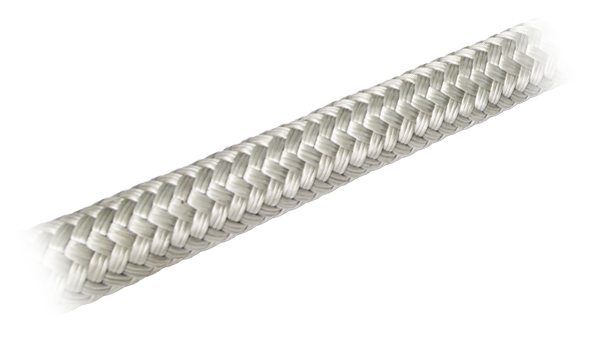

Acera™ daGama is constructed with a 12-strand core, with a tight 24 or 32 braided cover. The 3-step coating process ensures an outstanding resistance to particle ingress. It also protects against internal and external abrasion and prevents the core and cover from moving independently.

This cumbersome single yarn coating process demonstrates the uncompromising commitment to the quality standards of Acera™. Single yarn coating is proven to significantly enhance internal and external abrasion resistance, and extend service life and strength. 12 strand ropes are regarded as the best rope construction, and has become the most common construction for HMPE ropes. Acera™ Amundsen is the alternative to the cumbersome steel wire ropes. It is stronger and safer, with significantly less snap-back/recoil. The corresponding weight is therefore 7 times lower. When replacing conventional fiber ropes, the reduction in diameter leads to significant savings in weight (60%), space and handling. This reduces the total time required for mooring operations and fuel consumption.

The outer cover of the rope together with the inner sand filter helps to significantly reduce the negative impact of UV radiation on the rope and also increases the resistance to abrasion from the outside as well as from the inside.

Key Benefits

- Resistant to external damage and particle ingress

- Single yarn coating - high abrasion resistance

- Ease of handling

- High construction stability

- Well balanced; 6 left and 6 right strands

- No rotation under load

- Optional HT polyester cover available

Product Features

- Construction

-

12-strand plaited core

24 or 32 braided cover - Fiber

- Acera HMPE

- Specific gravity

-

ACERA cover 0,973 (floating)

PES cover 1,15 (sinking) - Colours

- Platinum

- UV resistance

- Excelent

- Abbrasion resistance

- Excelent

- Acid resistance

- Excelent

- Alkali resitance

- Excelent

- Most chemicals resistance

- Excelent

- Water resistance

- Excellent (0% absorption)

- Elongation

- Low (2-3% at break)

- Colours polyester cover

- White

- Colours Acera cover

- Platinum, Yellow

| diameter | MBL spliced | MBL spliced | MBL unspliced | MBL unspliced | diameter | MBL _spliced | MBL _unspliced | Weight |

|

Nominal

|

*

|

*

|

DIA.

|

*

|

||||

| (mm) | (t) | (kN) | (t) | (kN) | (inch) | (lbs) | (lbs) | (kg/m) |

| 6 | 3.7 | 36 | 4.1 | 40 | 1/4“ | 8.093 | 8.992 | 0.055 |

| 8 | 6.3 | 62 | 7 | 69 | 5/16“ | 13.961 | 15.512 | 0.085 |

| 10 | 9.7 | 95 | 10.7 | 105 | 13/32“ | 21.244 | 23.605 | 0.117 |

| 12 | 13.8 | 135 | 15.3 | 150 | 1/2“ | 30.349 | 33.721 | 0.156 |

| 14 | 18.4 | 180 | 20.4 | 200 | 9/16“ | 40.466 | 44.962 | 0.197 |

| 16 | 23.5 | 230 | 26 | 255 | 5/8“ | 51.594 | 57.326 | 0.236 |

| 18 | 29.1 | 285 | 32.1 | 315 | 3/4“ | 63.733 | 70.815 | 0.314 |

| 20 | 34.7 | 340 | 38.7 | 380 | 13/16“ | 76.884 | 85.427 | 0.370 |

| 22 | 41.3 | 405 | 45.9 | 450 | 7/8“ | 91.047 | 101.164 | 0.435 |

| 24 | 47.9 | 470 | 53 | 520 | 1“ | 105.210 | 116.900 | 0.502 |

| 26 | 55.1 | 540 | 61.2 | 600 | 1_1/16“ | 121.397 | 134.885 | 0.577 |

| 28 | 62.7 | 615 | 69.9 | 685 | 1_1/8“ | 138.594 | 153.994 | 0.653 |

| 30 | 71.4 | 700 | 79 | 775 | 1_1/4“ | 156.804 | 174.227 | 0.733 |

| 32 | 79.5 | 780 | 88.2 | 865 | 1_5/16“ | 175.013 | 194.459 | 0.817 |

| 34 | 88.7 | 870 | 98.4 | 965 | 1_3/8“ | 195.246 | 216.940 | 0.905 |

| 36 | 98.4 | 965 | 109.1 | 1070 | 1_1/2“ | 216.490 | 240.545 | 0.997 |

| 38 | 108.1 | 1060 | 119.8 | 1175 | 1_9/16“ | 237.735 | 264.150 | 1.092 |

| 40 | 117.8 | 1155 | 131 | 1285 | 1_5/8“ | 259.991 | 288.879 | 1.198 |

| 44 | 140.2 | 1375 | 155.5 | 1525 | 1_3/4“ | 308.550 | 342.833 | 1.420 |

| 48 | 163.2 | 1600 | 181 | 1775 | 2“ | 359.131 | 399.035 | 1.656 |

| 52 | 187.6 | 1840 | 208.5 | 2045 | 2_1/8“ | 413.760 | 459.733 | 1.909 |

| 56 | 213.6 | 2095 | 237.6 | 2330 | 2_1/4“ | 471.423 | 523.804 | 2.177 |

| 60 | 241.7 | 2370 | 268.7 | 2635 | 2_1/2“ | 533.133 | 592.370 | 2.462 |

| 64 | 270.7 | 2655 | 300.8 | 2950 | 2_5/8“ | 596.866 | 663.185 | 2.760 |

| 68 | 301.3 | 2955 | 335 | 3285 | 2_3/4“ | 664.646 | 738.496 | 3.106 |

| 72 | 333.4 | 3270 | 370.7 | 3635 | 3“ | 735.461 | 817.179 | 3.446 |

| 76 | 367.1 | 3600 | 407.9 | 4000 | 3_1/8“ | 809.310 | 899.234 | 3.803 |

| 80 | 401.8 | 3940 | 446.1 | 4375 | 3_1/4“ | 885.183 | 983.537 | 4.175 |

| 82 | 419.7 | 4116 | 466.3 | 4573 | 3_3/8“ | 925.236 | 1.028.040 | 4.368 |

| 88 | 475.2 | 4660 | 528.2 | 5180 | 3_5/8“ | 1.048.048 | 1.164.498 | 4.969 |

| 92 | 514.3 | 5044 | 571.5 | 5604 | 3_3/4 | 1.133.834 | 1.259.816 | 5.389 |

| 96 | 554.2 | 5435 | 615.9 | 6040 | 4“ | 1.222.048 | 1.357.831 | 5.825 |

| 100 | 596 | 5845 | 662.3 | 6495 | 4_1/16“ | 1.314.106 | 1.460.118 | 6.277 |

| 102 | 617.1 | 6052 | 685.7 | 6724 | 4_1/8“ | 1.360.439 | 1.511.599 | 6.508 |

| 104 | 638.9 | 6265 | 709.7 | 6960 | 4_1/4“ | 1.408.188 | 1.564.653 | 6.745 |

| 108 | 682.7 | 6695 | 758.7 | 7440 | 4_1/2“ | 1.505.304 | 1.672.560 | 7.227 |

| 110 | 705.1 | 6915 | 783.7 | 7685 | 4_9/16“ | 1.554.874 | 1.727.638 | 7.474 |

| 112 | 728.1 | 7140 | 811 | 7953 | 4_5/8“ | 1.609.097 | 1.787.886 | 7.725 |

| 116 | 774.3 | 7595 | 860.6 | 8440 | 4_3/4“ | 1.707.630 | 1.897.367 | 8.238 |

| 120 | 822.4 | 8065 | 913.7 | 8960 | 5“ | 1.812.840 | 2.014.266 | 8.767 |

* MBL guaranteed only for ropes spliced by TIMM ROPES

Customer service

We have the local knowledge and industry expertise to find the best solution to cater for your needs, do not hesitate to get in touch and ask for an advice.

+421 32 640 17 13 timm-sales@wilhelmsen.comCertificate